7 Easy Facts About Sandblasting Near Me Described

Table of ContentsSome Known Questions About Sandblasting Near Me.Unknown Facts About Sandblasting Near MeAn Unbiased View of Sandblasting Near MeSandblasting Near Me Things To Know Before You Get ThisSandblasting Near Me Can Be Fun For AnyoneWhat Does Sandblasting Near Me Do?Getting The Sandblasting Near Me To Work10 Easy Facts About Sandblasting Near Me Explained

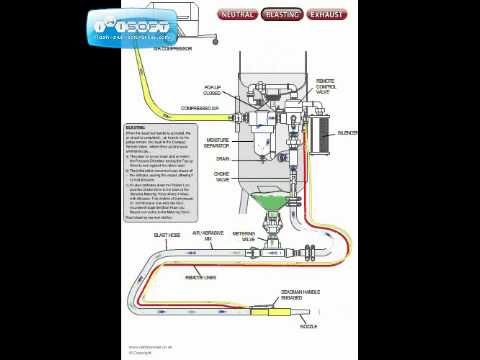

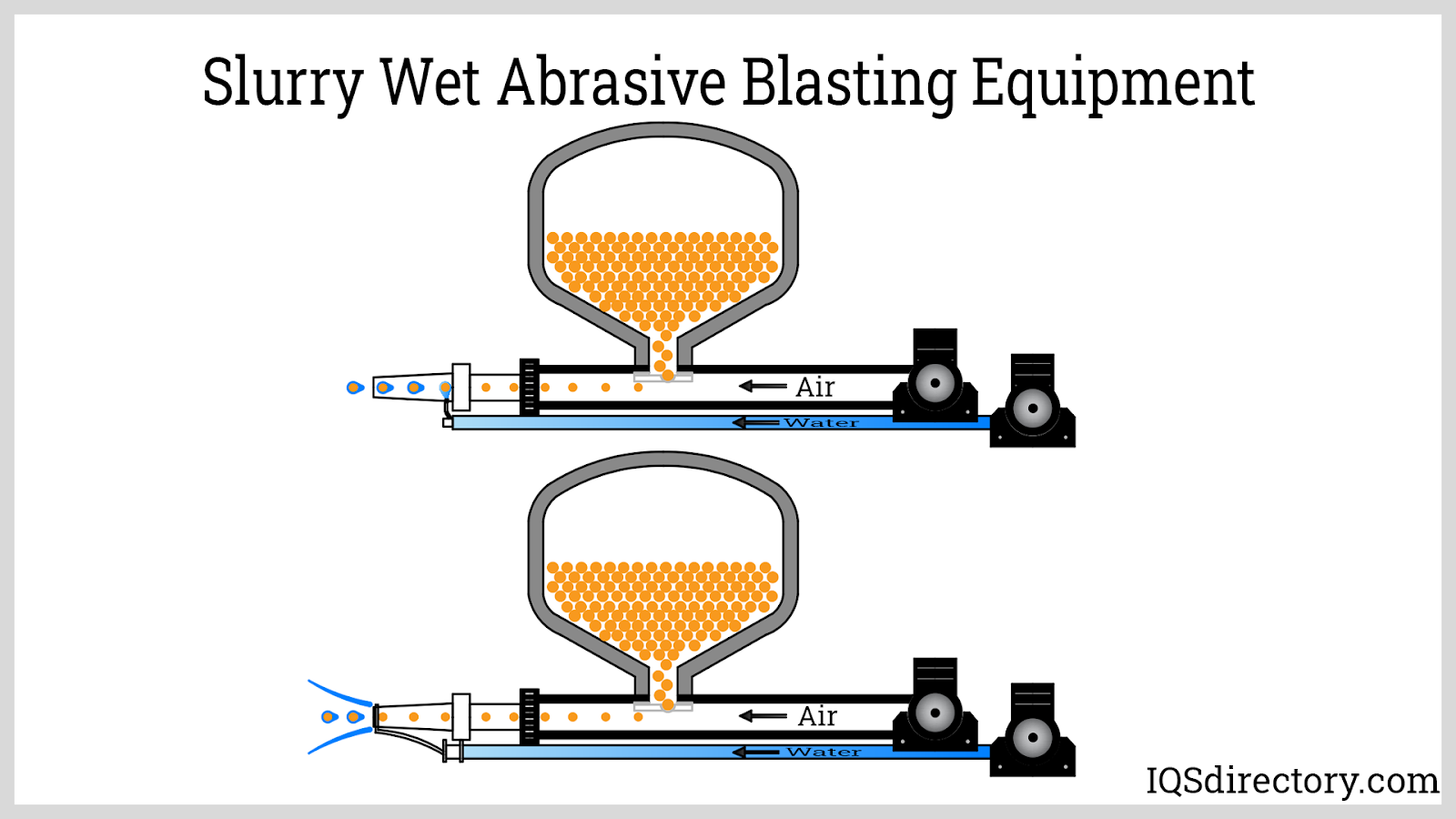

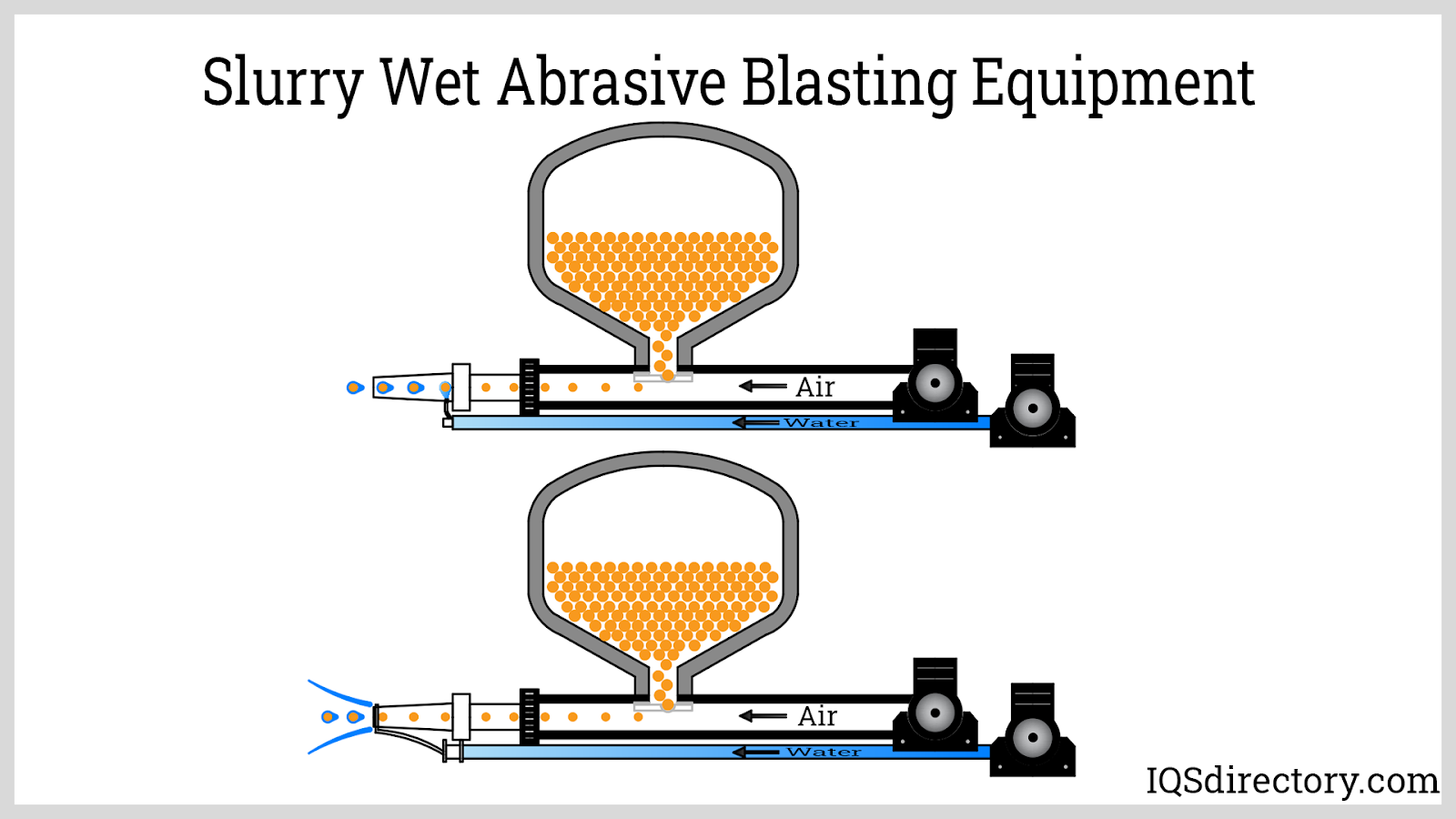

Sandblasting a rock wall surface Diesel powered compressor utilized as an air supply for sandblasting Abrasive blasting, more typically called sandblasting, is the operation of by force propelling a stream of abrasive product versus a surface area under high pressure to smooth a harsh surface, rough up a smooth surface, shape a surface area or eliminate surface area pollutants. An artificial sandblasting process was patented by Benjamin Chew Tilghman on 18 October 1870. Sandblasting equipment usually includes a chamber in which sand and also air are mixed. The blend travels via a hand-held nozzle to guide the bits towards the surface or job item. Nozzles are available in a selection of shapes, sizes, as well as products.Wet unpleasant blowing up [modify] Damp abrasive blasting uses water as the liquid relocating the abrasives. The benefits are that the water traps the dirt generated, and oils the surface. The water supports the effect on the surface area, reducing the elimination of sound product. One of the original pioneers of the damp unpleasant procedure was Norman Ashworth who found the advantages of using a damp process as a strong option to completely dry blasting.

Sandblasting Near Me Things To Know Before You Get This

A variation of wet blowing up is vapor blasting (or vapour blasting; U.K.). In this procedure pressurized air is added to the water in the nozzle generating a high speed mist, called "vapor". This procedure is even milder than wet blasting, permitting mating surface areas to be cleaned up while keeping their capacity to mate.

4 Easy Facts About Sandblasting Near Me Explained

Mixing particles with water substantially lowers dirt. Bead blasting is the procedure of removing surface deposits by using great glass beads at a high stress without damaging the surface.

In getting rid of paint for vehicle body work, grain blasting is favored over sand blasting, as sand blasting has a tendency to produce a better surface area account than grain blasting. Grain blasting is typically used in producing a consistent surface area coating on machined components.

Some Known Details About Sandblasting Near Me

The very first blast wheel was patented by Wheelabrator in 1932. Hydro blowing up is not a type of unpleasant blasting as no unpleasant media is utilized. Hydro-blasting, commonly known as water blasting, is frequently used since it generally calls for only one driver.

This technique is optimal for cleaning inner and external surfaces due to the fact that the driver is generally able to send out the stream of water right into areas that are difficult to get to using other methods. One more benefit of hydro-blasting is the capacity to recapture and also reuse the water, lowering waste and also mitigating environmental effect.

The Best Guide To Sandblasting Near Me

The most common micro-abrasive blasting systems are commercial bench-mounted units being composed of a power supply and also mixer, exhaust hood, nozzle, as well as gas supply. Either the here are the findings nozzle or component can be moved in automatic procedure - sandblasting near me.

The Main Principles Of Sandblasting Near Me

Others are receptacle-fed types making them lightweight and also extra mobile. In wet blasting, the abrasive is presented right into a pressurized stream of water or various other liquid, developing a slurry. Wet blowing up is frequently used in applications where the minimal dirt click here for more generation is preferred. Portable applications might or may not recycle the unpleasant.

Little Known Facts About Sandblasting Near Me.

It usually contains 4 elements; the containment (closet), the abrasive blasting system, the rough recycling system and the dust collection. The operator blasts the parts from the beyond the closet by positioning his arms in gloves affixed to handwear cover holes on the cupboard, checking out the part with a sight home window, transforming the blast on as well as off making use of a foot pedal or treadle.

There are 3 systems generally utilized in a blast cabinet. Two, siphon as well as pressure, are dry and also one is damp: A siphon blast system (suction blast system) makes use of the pressed air to produce vacuum cleaner in a chamber (understood as the blast weapon). The unfavorable pressure pulls rough into the blast weapon where the compressed air guides the abrasive through a blast nozzle.

The Ultimate Guide To Sandblasting Near Me

Silicon carbide and boron carbide nozzles are a lot more wear immune as well as are often used with harder abrasives such as aluminium oxide. Low-cost rough blasting systems as well as smaller closets use ceramic nozzles.

The vessel is pressurized to the very same stress as the blast hose pipe connected to all-time low of the stress vessel. The unpleasant is metered into the blast tube as well as shared by the compressed gas via the blast nozzle. Wet blast cabinets make use of a system that injects the abrasive/liquid slurry into a pressed gas stream.